WELCOME TO OUR COMPANY

Heavy Equipment

& Small Tools

for Different Needs

We carry equipment rental products for contractors and homeowners

Get a Free Quote.

Our Products

HAND PALLET TRUCK

ELECTRIC PALLET TRUCK

WALKIE FULLY ELECTRIC STACKER

SEMI ELECTRIC STACKER

MANUAL STACKER

PAPER ROLL STACKER

ELECTRIC FLOOR CRANE

DRUM HANDLING EQUIPMENT

SCISSOR LIFT TABLE

TERRAIL PALLET TRUCK

BAND SEALER

SHRINK MACHINE

AUTOMATIC SHRINK MACHINE

LIQUID FILLING MACHINE

PASTE FILLING MACHINE

VACUUM MACHINE

PACKAGING MACHINE

PACKAGING MACHINE

STRECH WRAPPING MACHINE

GRANULE MACHINE

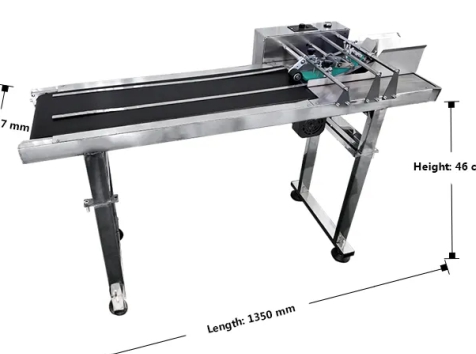

LABELLING MACHINE

Our Features

We allows you to make an equipment rental reservation with us any time you need it. Browse through our equipment rental categories and pick those equipment rental items that you will need and we will have the reservation in our store in minutes.

Maintenance

Machine maintenance is a critical process that involves regular inspections, repairs, and upkeep to ensure machines remain in optimal working condition.

It is essential for various industries, including manufacturing, construction, and healthcare, to maximize equipment reliability, safety, and efficiency. Key aspects of machine maintenance include preventive actions, such as routine checks, cleaning, lubrication, and calibration, as well as reactive maintenance to address unexpected breakdowns promptly. Proper maintenance extends machine lifespan, reduces downtime, and can ultimately lead to significant cost savings by preventing costly repairs and replacements. Effective maintenance practices are typically guided by schedules, checklists, and records to track maintenance activities and equipment performance over time.

Major Repairs

Major machine repairs involve in-depth troubleshooting, dismantling, and restoration of critical components or systems within a machine. These repairs are typically required in the following situations:

Extensive Damage: Major repairs are needed when a machine has suffered severe damage or wear, affecting its functionality and performance.

Component Replacement: This may involve replacing major components such as engines, transmissions, or critical electronic components to restore the machine to working order.

Warranty Service

Warranty service for machines is a customer-oriented support provided by manufacturers or sellers to address issues with the machine during a specified period after purchase.

Duration: Warranties have a defined duration, often ranging from a few months to several years, depending on the type of machine and its manufacturer. Common warranty periods include one year, three years, or more.

Coverage: The warranty document outlines what aspects of the machine are covered. This may include parts, labor, and specific issues that are eligible for repair or replacement. Some warranties are comprehensive, while others are limited in scope.

Conditions: Warranties often come with conditions that must be met for the warranty to remain valid. These conditions may include proper maintenance, using the machine as intended, and not tampering with it.

Equipment inspections

Equipment inspections for machines are systematic examinations and assessments conducted on machinery to ensure they are in proper working order, meet safety standards, and comply with regulations.

Safety: Ensure that machines are safe to operate, minimizing the risk of accidents or injuries to operators and bystanders.

Reliability: Identify and address potential issues or wear-and-tear that could lead to machine breakdowns, reducing downtime.

Compliance: Ensure that machines meet industry standards, regulatory requirements, and manufacturer specifications.

Safety

Machine safety is of paramount importance in any industrial or manufacturing setting. It involves measures and practices aimed at protecting workers, operators, and the environment from potential hazards associated with machinery.

Worker Protection: Ensures the well-being and physical safety of operators and workers who interact with machines, reducing the risk of accidents, injuries, and fatalities.

Compliance: Helps organizations adhere to legal requirements and industry standards related to workplace safety and machinery operation, avoiding costly penalties and legal liabilities.

Delivery

Transportation: Delivery typically involves the use of specialized transportation methods suited to the size, weight, and type of the machine. This can include trucks, trailers, cranes, or other heavy equipment transport vehicles.

Preparation: Before delivery, the machine is often prepared for transport. This may involve securing loose parts, disassembling components if necessary, and ensuring it is adequately packaged or protected to prevent damage during transit.

Logistics: Logistics planning is essential for a smooth delivery process. This includes scheduling the delivery to align with project timelines, arranging for permits if needed, and considering factors such as road conditions and route accessibility.

Need a Consultation? Our Professionals Are Always Ready to Help You, Contact Us Today!

Get a Free Quote.

Hear From our Clients

KGRK Enterprises is truly the best. I have been perusing your site and contemplating another order

Address

Near Dhingra Rice Mill, Umri Chowk,

Kurukshetra, Haryana, India - 136118

sales@kgrkenterprises.com

Online Support

Phone

- Near Dhingra Rice Mill, Umri Chowk, Kurukshetra, Haryana, India - 136118

- +91 9599604924

- sales@kgrkenterprises.com

GET IN TOUCH

Give us a Call or fill up the form above and our team will contact you in few Hours.