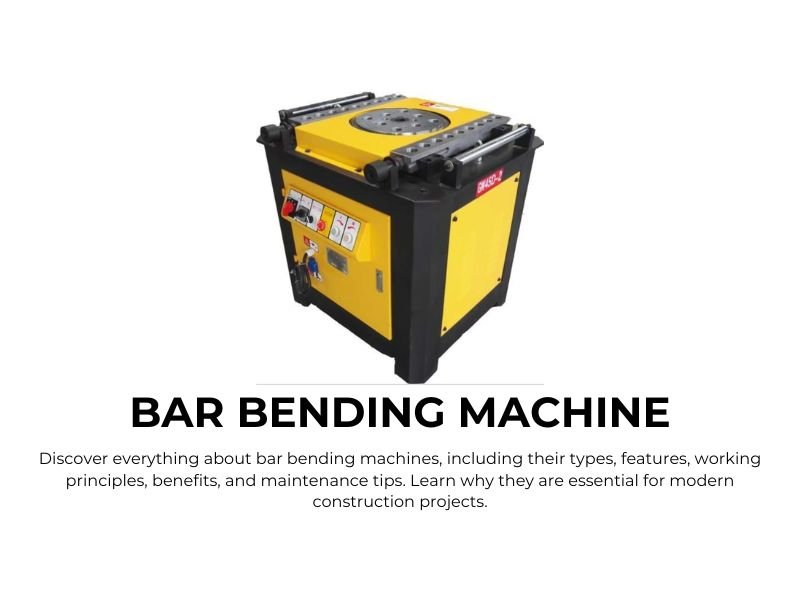

Discover the top 10 benefits of using bar cutting machines for large-scale projects. Learn how these advanced tools improve efficiency, precision, safety, and cost-effectiveness in construction.

Large-scale construction projects require exceptional precision, efficiency, and safety. From bridges and skyscrapers to massive industrial complexes, the backbone of these structures often lies in reinforced concrete, which relies on steel reinforcement bars (rebar). Cutting and shaping these bars accurately and efficiently is a critical step in the construction process, and that’s where bar cutting machines play an indispensable role.

In this article, we will explore the top 10 benefits of using bar cutting machines in large-scale projects, shedding light on how they streamline operations, reduce costs, and enhance safety. We will also discuss their impact on sustainability and overall project timelines.

1. Precision and Accuracy

One of the most significant advantages of bar cutting machines is their ability to deliver unmatched precision. Accurate cutting of rebars is essential for ensuring the structural integrity of buildings and other infrastructure.

- Improved Fit: Precise cuts ensure the bars fit perfectly into the design requirements, minimizing structural issues.

- Consistency: Automated bar cutting machines provide uniform results, which are critical in repetitive cutting tasks.

- Minimal Waste: Precise cutting reduces material wastage, thereby saving costs and reducing environmental impact.

2. Enhanced Efficiency

Manual cutting of rebars can be time-consuming and labor-intensive. Bar cutting machines, on the other hand, significantly improve efficiency.

- High-Speed Operations: Machines can cut multiple bars quickly, reducing project timelines.

- Automation: With programmable settings, these machines can operate with minimal supervision.

- Reduced Downtime: Modern bar cutting machines are designed to perform continuous operations with minimal maintenance.

3. Cost-Effectiveness

While the initial investment in bar cutting machines may seem high, the long-term savings justify the expense.

- Reduced Labor Costs: Automation reduces the need for large manual labor teams.

- Less Material Waste: Precision cutting minimizes errors, reducing the cost of rework and material wastage.

- Energy Efficiency: Advanced machines are designed to consume less energy, further cutting operational costs.

4. Improved Safety

Safety is a top priority in any construction project. Bar cutting machines significantly enhance workplace safety compared to manual cutting methods.

- Minimized Risk of Injuries: Machines eliminate the need for workers to use potentially dangerous handheld tools.

- Stable Operations: Features like emergency stop buttons and protective shields ensure safe operation.

- Reduced Fatigue: Automation reduces physical strain on workers, minimizing accidents caused by exhaustion.

5. Versatility

Bar cutting machines are designed to handle various types and sizes of reinforcement bars.

- Adjustable Settings: Operators can easily adjust the machine for different diameters and lengths.

- Compatibility: They can cut various materials, including mild steel, stainless steel, and galvanized iron.

- Custom Cuts: Machines can perform straight cuts, angled cuts, and even complex shapes as required by the project design.

6. Consistency and Reliability

Large-scale projects often require thousands of bars to be cut with identical specifications. Bar cutting machines ensure consistent results every time.

- Programmed Accuracy: Machines follow predefined instructions to deliver uniform cuts.

- Reduced Human Error: Automation eliminates inconsistencies caused by manual intervention.

- Dependability: Modern machines are built to withstand heavy-duty usage, ensuring reliability even under demanding conditions.

7. Time-Saving

Time is money in construction, and bar cutting machines help save both.

- Quick Setup: Machines are easy to set up and operate, reducing initial preparation time.

- High Throughput: Their ability to cut multiple bars in rapid succession accelerates project timelines.

- Streamlined Workflow: By integrating with other construction equipment, these machines create a seamless workflow.

8. Eco-Friendliness

Sustainability is a growing concern in construction, and bar cutting machines contribute positively to this aspect.

- Waste Reduction: Precise cutting minimizes scrap material.

- Energy Efficiency: Newer models consume less power, contributing to lower carbon footprints.

- Recyclability: Reduced waste enhances the recyclability of unused materials.

9. Adaptability to Project Scale

Whether you’re working on a small building or a massive infrastructure project, bar cutting machines can scale up to meet your needs.

- Compact Models for Small Projects: Smaller machines are available for limited space and modest requirements.

- Heavy-Duty Machines for Large Projects: Industrial-grade machines handle extensive workloads efficiently.

- Custom Solutions: Manufacturers offer customizable machines tailored to specific project needs.

10. Longevity and Durability

Investing in high-quality bar cutting machines ensures long-term usage and performance.

- Robust Construction: Machines are built with durable materials like cast iron and stainless steel.

- Low Maintenance: Advanced models require minimal upkeep, reducing downtime and repair costs.

- Extended Lifespan: With proper care, these machines can serve multiple projects over many years.

Conclusion

The use of bar cutting machines in large-scale construction projects is a game-changer. From improving precision and efficiency to enhancing safety and sustainability, these machines have become indispensable tools for modern construction. Their versatility, cost-effectiveness, and ability to scale with project demands make them a must-have for any construction company aiming for excellence.

Investing in a reliable bar cutting machine not only streamlines operations but also boosts overall productivity, ensuring projects are completed on time and within budget. As the construction industry continues to embrace automation and innovation, the importance of these machines will only grow.