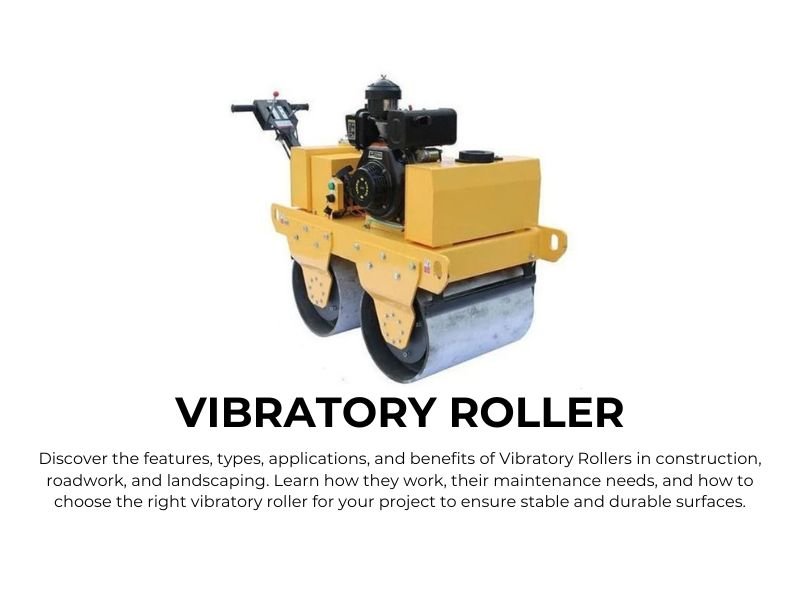

Vibrating rollers play a crucial role in asphalt compaction, improving road longevity and quality. Learn about their importance, types, benefits, and applications in this detailed guide.

Vibrating rollers, also known as vibratory rollers, are critical pieces of construction equipment used to compact and stabilize asphalt and soil during the construction of roads, highways, and other infrastructure projects. Their primary function is to apply dynamic force to the material being compacted, which helps achieve the desired density, reduce air voids, and improve the overall strength of the pavement. By using a combination of vibration and weight, vibrating rollers efficiently compact the asphalt, enhancing road durability, smoothness, and performance.

The importance of vibrating rollers in asphalt compaction cannot be overstated. These machines ensure that the asphalt layers are uniformly compacted, leading to improved load-bearing capacity and extended service life. This article delves deeper into the role of vibrating rollers, their types, benefits, and how they contribute to quality asphalt compaction in road construction.

How Vibrating Rollers Work

Vibrating rollers operate on a simple but effective mechanism. The machine consists of large steel drums mounted on the front and rear, which generate both static and dynamic compaction forces. The vibration is produced by an eccentric weight mechanism within the drum, which causes the roller to vibrate rapidly as it moves across the surface. This vibration breaks down air pockets and promotes the interlocking of particles in the asphalt, leading to a denser and more stable surface.

The process involves the following steps:

- Vibration Initiation: The vibrating roller’s drum generates vibrations at a high frequency, which increases the compaction energy.

- Surface Pressure: The weight of the machine combined with the vibrations compacts the asphalt and smooths the surface.

- Continuous Compaction: The roller moves across the asphalt multiple times to ensure uniform compaction throughout the layer.

This combination of weight and vibration provides superior compaction compared to traditional methods, making vibrating rollers indispensable for road construction projects.

Types of Vibrating Rollers

Vibrating rollers are available in different types to suit various applications and material conditions. The key types include:

- Single Drum Rollers:

Single drum rollers are the most common type of vibrating rollers used in road construction. They consist of one large vibrating drum in the front, while the rear part is usually equipped with a smooth drum or pneumatic tires. These rollers are primarily used for compacting asphalt, gravel, and soil. - Double Drum Rollers:

As the name suggests, double drum rollers feature two vibrating drums—one at the front and one at the rear. These machines are more versatile as they offer compaction on both sides of the roller, ensuring better coverage. They are particularly effective for working on smaller, narrower spaces like curbs, gutters, and sidewalks. - Padfoot Rollers:

Padfoot rollers, also known as sheepsfoot rollers, have a unique drum design with projections or pads on the surface. These rollers are particularly useful for compacting granular materials such as soil, gravel, or crushed stone. The protrusions on the drum help break down the material and ensure deeper penetration. - Combination Rollers:

Combination rollers combine both smooth and padfoot drums, making them adaptable for different applications. They offer flexibility for compaction of both granular materials and asphalt.

Benefits of Vibrating Rollers in Asphalt Compaction

- Improved Compaction Efficiency:

Vibrating rollers significantly improve the efficiency of asphalt compaction. The vibration mechanism ensures that more material is compacted in less time, reducing the number of passes needed compared to static rollers. - Higher Density and Durability:

The vibration ensures that asphalt is compacted uniformly and tightly, resulting in a higher density. A denser asphalt layer improves the strength of the pavement and its ability to resist traffic loads, reducing the likelihood of surface cracking and deterioration. - Better Surface Quality:

Vibrating rollers create a smoother surface finish by eliminating air pockets and inconsistencies in the asphalt. This leads to improved road smoothness, better ride quality for vehicles, and longer-lasting pavements. - Reduced Segregation:

Segregation refers to the uneven distribution of aggregates within the asphalt mix, which can lead to weaker spots on the surface. Vibrating rollers help prevent segregation by ensuring a more uniform mix, contributing to a longer-lasting, high-quality road surface. - Cost-Effective Solution:

While vibrating rollers may require a larger initial investment compared to traditional rollers, their ability to complete the job more efficiently means they ultimately save time and labor costs. Fewer passes are needed, and the work is completed faster, which speeds up the overall project timeline. - Versatility in Applications:

Vibrating rollers are versatile and can be used for both asphalt and soil compaction. This versatility makes them a valuable asset for a wide range of construction projects, from road construction to building foundations. - Enhanced Safety:

By achieving the desired compaction quickly and uniformly, vibrating rollers help ensure that roads are strong and stable, reducing the risk of accidents caused by road defects or uneven surfaces.

Applications of Vibrating Rollers

Vibrating rollers are employed in a variety of construction applications, including:

- Road Construction:

Vibrating rollers are widely used in road construction to compact asphalt layers. Their primary role is to ensure the asphalt is compacted to the desired density, improving the strength and longevity of the road. - Paving:

Vibrating rollers are essential in the paving process for both highways and city roads. They compact freshly laid asphalt to create a smooth and durable surface. - Airport Runways:

The high-density compaction achieved by vibrating rollers is critical in constructing strong, durable runways capable of withstanding the heavy loads imposed by aircraft. - Parking Lots and Driveways:

Smaller vibrating rollers are used for compacting asphalt in parking lots, driveways, and smaller road sections, ensuring a solid, smooth, and stable surface. - Foundation Construction:

Vibrating rollers can also be used for compacting the base materials in foundation construction, ensuring a strong foundation for buildings and structures.

Conclusion

Vibrating rollers are indispensable tools in the world of asphalt compaction, offering numerous benefits for road construction projects. From improving compaction efficiency to enhancing road durability, these machines play a critical role in creating smooth, stable, and long-lasting asphalt surfaces. Understanding their importance and the various types available can help contractors select the right equipment for the job, leading to better outcomes and higher-quality roads.