Get quick, personalized assistance for all your CONSTRUCTION EQUIPMENTS MACHINES like Mini vibratory roller compactor needs—enquire now and let’s get started!

OUR BEST SELLERS

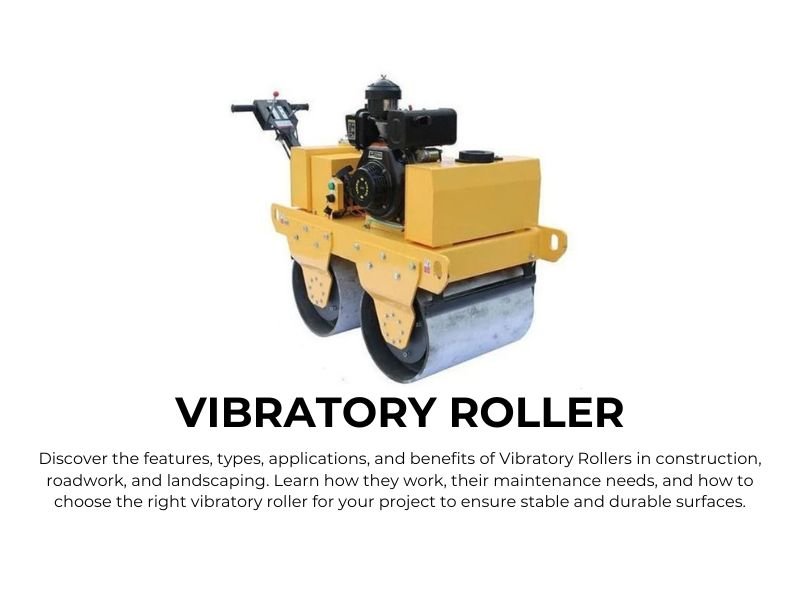

mini vibratory roller compactor

The Mini Vibratory Roller by KGRK Enterprises is a compact powerhouse built to get the job done—quickly, reliably, and without the hassle. Whether you’re working on a narrow lane, a small site, or a patch repair job, this machine is made to fit where big rollers can’t—and still deliver a solid, professional finish.

Designed with real-world construction challenges in mind, it tackles soil, asphalt, and granular surfaces with ease. Its strong vibration system ensures tight compaction, reducing the number of passes and saving both time and fuel.

Easy to operate, rugged in build, and low on maintenance, this roller is perfect for contractors, roadwork teams, and anyone who needs dependable performance in tight spots. With the Mini Vibratory Roller from KGRK, you don’t just get a machine—you get peace of mind on the jobsite.

Specifications

| Specification | FVR 600S | FVR 600 | FVR 850 | FVR 1000 | FVR 1200 | |

|---|---|---|---|---|---|---|

| Package Size (mm) | 1380 × 920 × 1100 | 1370 × 980 × 1200 | 2100 × 1000 × 1400 | 2100 × 1000 × 1450 | 2100 × 1000 × 1650 | |

| Centrifugal Force | 15 kN | 30 kN | 30 kN | 50 kN | 50 kN | |

| Starting System | Manual | Electric | Electric | Electric | Electric | |

| Drive Type | Hydraulic | Hydraulic | Hydraulic | Mechanical | Hydraulic | |

| Water Tank Capacity | 30 Ltr. | 35 Ltr. | 35 Ltr. | 60 Ltr. | 60 Ltr. | |

| Working Direction | Forward & Backward | Forward & Backward | Forward & Backward | Forward & Backward | Forward & Backward | |

| Working Speed | 0–4 km/h | 0–4 km/h | 0–5 km/h | 0–8 km/h | 0–8 km/h | |

| Engine | 5.5 Hp Greaves/Honda | 9 Hp Greaves | 9 Hp Greaves | 9 Hp Chengfa | 13 Hp Chengfa | |

| Vibration Frequency | 70 Hz | 70 Hz | 70 Hz | 70 Hz | 70 Hz | |

| Vibrating Clutch | Automatic | Automatic | Electrum | Electrum | Electrum | |

| Fuel Tank Capacity | 2.5 Ltr. | 3.6 Ltr. | 3.6 Ltr. | 5 Ltr. | 5 Ltr. | |

| Wheel Size (mm) | 430 × 600 | 430 × 600 | 580 × 700 | 540 × 700 | 540 × 800 | |

| Machine Weight | 280 kg | 550 kg | 750 kg | 1000 kg | 1200 kg | |

| Gradeability | 25% | 30% | 30% | 30% | 30% | |

| Operation Type | Walk-behind | Walk-behind | Ride-on | Ride-on | Ride-on | |

| Ideal Applications | Patchwork, Small Sites | Internal Roads, Edges | Roads, Yards | Asphalt Roads, Driveways | Roadwork, Construction |

Leading the way

Why KGRK Enterprises?

We are dedicated to providing the best quality and innovative machinery for the construction and industrial sectors. With over ten years of experience, we understand what our customers need.

Our wide range of products, from construction machines to industrial equipment, meets the highest standards for performance and durability.

Quality

Innovation

Reliability

Variety

Customization

Support

Our journey is driven by a commitment to connecting innovations with the needs of our clients. We strive to craft solutions that empower industries and elevate standards, ensuring every product we offer embodies our dedication to delivering excellence. As we look to the future, we remain steadfast in our mission to provide high-quality industrial equipment that not only meets but exceeds expectations. Together with our partners and customers, we will continue to innovate, inspire, and build a better world for all.