Explore the indispensable role of stirrup ring bending machines in construction, their applications, use cases, benefits, and how they revolutionize modern construction practices with enhanced precision, efficiency, and safety.

In the world of modern construction, precision and efficiency are paramount. Reinforced concrete is the backbone of almost all infrastructure projects, from towering skyscrapers to durable bridges. A critical component of reinforced concrete is the stirrup—a ring-shaped rebar that provides lateral support to the main bars and holds the concrete in place.

Creating these stirrups manually is a time-consuming and error-prone task. Enter the stirrup ring bending machine, a revolutionary tool that automates this process, ensuring precision and speed. This article delves deep into the role of stirrup ring bending machines in construction, exploring their benefits, applications, and transformative impact on the industry.

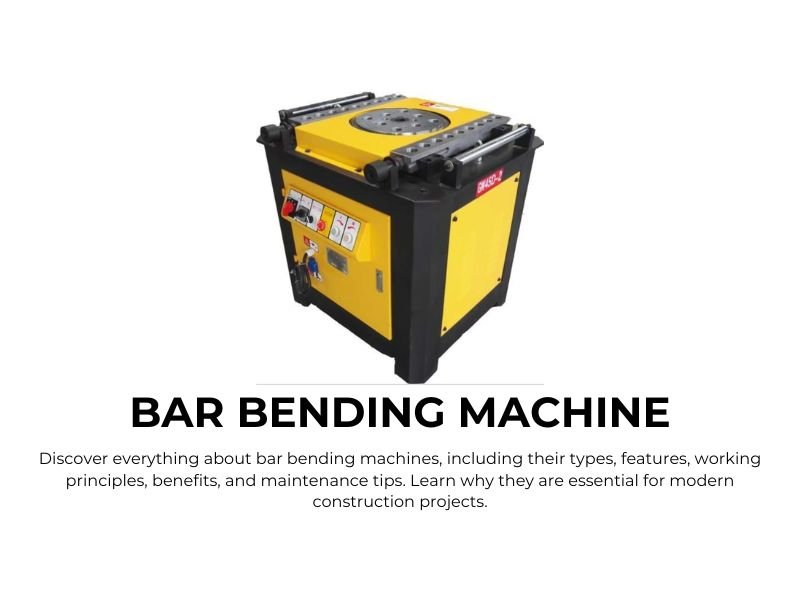

What Is a Stirrup Ring Bending Machine?

A stirrup ring bending machine is a specialized mechanical device designed to bend steel reinforcement bars (rebars) into precise shapes, primarily rings, rectangles, or other configurations. These machines are essential for creating the stirrups used in reinforced concrete structures.

The process involves feeding a steel bar into the machine, which then bends it to the desired shape and size according to pre-set specifications. These machines come in various forms, including manual, semi-automatic, and fully automatic models, catering to different project scales and requirements.

Key Features of Stirrup Ring Bending Machines

- Precision Bending:

Machines can produce uniform bends with exact dimensions, reducing the risk of errors that compromise structural integrity. - High-Speed Operation:

Automated processes significantly enhance productivity by bending multiple stirrups in a short time. - Customizable Settings:

Advanced models offer programmable settings for various shapes and sizes, catering to diverse project needs. - Durable Construction:

Designed for heavy-duty use, these machines can handle high workloads and resist wear and tear. - Safety Features:

Integrated safety mechanisms, such as emergency stop buttons and protective shields, ensure operator safety.

The Role of Stirrup Ring Bending Machines in Construction

Stirrup ring bending machines have become indispensable in construction for several reasons:

- Reinforcement Precision:

Accurate stirrups ensure even stress distribution, enhancing the strength and durability of concrete structures. - Time Efficiency:

Manual bending is labor-intensive and slow. Automated machines drastically reduce the time required to prepare reinforcement materials. - Cost Savings:

By minimizing material waste and labor requirements, these machines lower overall project costs. - Safety Improvement:

Reducing manual handling of rebars decreases the risk of workplace injuries. - Sustainability:

Machines optimize material usage, contributing to eco-friendly construction practices.

Applications of Stirrup Ring Bending Machines

Stirrup ring bending machines are versatile tools with applications across various construction projects:

- Residential Buildings:

- Ensure uniform reinforcement in beams, columns, and foundations for houses and apartments.

- Enhance structural stability, especially in earthquake-prone areas.

- Commercial Buildings:

- Support the construction of office spaces, malls, and industrial units.

- Provide the required strength for multi-story buildings.

- Infrastructure Projects:

- Essential for bridges, flyovers, and tunnels, where precision reinforcement is critical.

- Contribute to the durability of large-scale infrastructure.

- Industrial Constructions:

- Reinforce heavy-load structures like warehouses, factories, and power plants.

- Handle large quantities of stirrups efficiently for industrial-scale projects.

- Specialized Structures:

- Ideal for creating complex designs in architectural projects.

- Used in constructing dams and high-stress load structures.

Use Cases of Stirrup Ring Bending Machines

Case 1: High-Rise Building Construction

In a high-rise project, thousands of stirrups are required to reinforce the columns and beams. A stirrup ring bending machine automates this process, producing consistent, high-quality stirrups in bulk. This saves time, reduces labor costs, and ensures the structure’s reliability.

Case 2: Bridge Reinforcement

Bridges require precision-engineered stirrups to handle dynamic loads. Stirrup bending machines ensure that every piece meets exact specifications, enhancing the bridge’s lifespan and safety.

Case 3: Industrial Warehouse Project

A large warehouse project demands quick turnaround times and cost-efficiency. By deploying stirrup ring bending machines, the contractor ensures timely delivery of reinforcement materials without compromising quality.

Case 4: Earthquake-Resistant Structures

In earthquake-prone regions, reinforced structures need precise stirrups to withstand seismic forces. Stirrup machines provide consistent reinforcements, reducing vulnerability to structural failure.

Benefits of Using Stirrup Ring Bending Machines

- Enhanced Structural Integrity:

- Accurate bends ensure even stress distribution and stronger structures.

- Increased Productivity:

- Automation enables faster production, keeping projects on schedule.

- Reduced Labor Dependency:

- Machines minimize the need for manual labor, especially in repetitive tasks.

- Lower Material Wastage:

- Precise bending reduces the scrap generated during construction.

- Improved Safety Standards:

- Operators are less exposed to risks associated with manual bending.

- Customizable Outputs:

- Machines can adapt to different designs and specifications with ease.

Choosing the Right Stirrup Ring Bending Machine

When selecting a stirrup ring bending machine, consider the following factors:

- Project Scale:

- Determine the volume of stirrups required and choose a machine with suitable capacity.

- Bar Sizes:

- Ensure the machine can handle the diameter and length of rebars used in your project.

- Automation Level:

- For large-scale projects, fully automatic machines offer the best efficiency.

- Budget:

- Balance the upfront cost with long-term savings from reduced labor and waste.

- Brand and Support:

- Choose a reliable manufacturer with excellent customer service and warranty.

Challenges and Solutions

Challenge: High Initial Investment

Solution: Consider leasing options or calculate long-term savings to justify the cost.

Challenge: Operator Training

Solution: Provide basic training to staff or opt for user-friendly models with intuitive controls.

Challenge: Maintenance Requirements

Solution: Regularly inspect and maintain the machine to ensure uninterrupted performance.

Conclusion

Stirrup ring bending machines are a game-changer in the construction industry. Their ability to produce precise, high-quality reinforcements quickly and safely makes them indispensable for modern projects. Whether you are working on a small residential building or a large infrastructure project, investing in a stirrup ring bending machine ensures efficiency, cost savings, and superior construction quality.

By adopting this innovative technology, construction companies can stay competitive, meet project deadlines, and contribute to sustainable building practices.